Have you ever wondered about the amount of electricity your well pump consumes? If you own a 1.5 HP well pump, then you’ll be interested to know how many amps it uses. A well pump is an essential device that pumps water from a well into your home. This process requires an electric pump that can generate enough energy to lift the water.

To determine their pumping capacity, well pumps use horsepower. In this context, a 1.5 HP well pump refers to a motor with a power output of 1.5 horsepower. But when it comes to electricity consumption, you might wonder how much energy is needed to run this pump.

The number of amps that a 1.5 HP well pump uses depends on several factors, including the voltage and motor size. The voltage of your well pump can be either 110 or 220 volts, while the motor size can range from 1.5 to 2 horsepower. It’s essential to understand how many amps your well pump uses because it helps in connecting it to a generator or inverter with specific power ratings.

In this blog post, we’ll take a deep dive into how many amps a 1.5 HP well pump uses and the factors affecting its energy draw. We’ll also show you how to calculate the electricity consumption of your well pump so that you can make informed decisions about powering it up.

So sit tight and get ready for an informative ride as we explore everything you need to know about the amp usage of a 1.5 HP well pump.

What is a 1.5 HP Well Pump?

Contents

- 1 What is a 1.5 HP Well Pump?

- 2 Factors that Affect the Amperage of a 1.5 HP Well Pump

- 3 How to Calculate the Amperage of a 1.5 HP Well Pump

- 4 The Average Amperage Draw of a 1.5 HP Well Pump

- 5 Variations in Amperage Draw Depending on Load

- 6 Ensuring Your Electrical System Can Support Your Well Pump

- 7 Conclusion

Get ready to say goodbye to water supply issues with the powerful 1.5 HP well pump. This type of water pump is a popular choice for extracting water from underground sources, such as wells and boreholes, thanks to its reliable and efficient performance.

The 1.5 HP well pump gets its name from the horsepower of the motor that drives the pump. It’s designed to provide enough power to extract water from deep underground sources, making it ideal for residential and commercial settings where large amounts of water need to be pumped regularly. Plus, it’s built to last with durable materials like cast iron, stainless steel, or thermoplastic that can withstand harsh environmental conditions.

But what makes the 1.5 HP well pump stand out from other types of pumps? Its impressive capacity to pump up to 25 gallons of water per minute, depending on the depth of the well and size of the pump. With this kind of power, it’s perfect for households with high water demand or large commercial properties that require a steady supply of water.

If you’re wondering about the amperage of a 1.5 HP well pump, it typically uses between 10 and 15 amps of electricity. You can confirm the amperage draw by checking the manufacturer’s specifications or using an ammeter to measure the electrical current while the pump is running.

Factors that Affect the Amperage of a 1.5 HP Well Pump

If so, a 1.5 HP well pump may be just what you need. But before you make any decisions, it’s essential to understand the factors that can impact the amperage requirement of this powerful device.

Firstly, the voltage supplied to the pump has a direct impact on its amperage requirement. Most 1.5 HP well pumps operate at either 115V or 230V, with the latter being more common. When the voltage is increased, the amperage requirement decreases, and vice versa. So, it’s important to ensure that the voltage supplied is appropriate for your pump to avoid any electrical issues.

Secondly, the depth of your well can also affect the amperage requirement of your pump. As the depth increases, so does the head pressure required to lift water to the surface. This increased pressure can result in higher amperage requirements for the pump. Therefore, it’s crucial to determine the depth of your well and choose a pump with an appropriate amperage rating.

Thirdly, the type of pump used can also impact amperage requirements. Submersible pumps are typically more efficient and require less amperage than jet pumps. So, when selecting a pump type, it’s essential to consider your unique well system and choose one that aligns with your needs and budget.

Fourthly, the size of pipes transporting water from the well to the surface can affect amperage requirements. Smaller pipes create more resistance, leading to increased amperage requirements. Hence, it’s necessary to select appropriately sized pipes that minimize resistance and optimize efficiency.

Lastly, the level of the water table can impact amperage requirements. If the water table is low, pumps will have to work harder to draw water from the well, resulting in higher amperage requirements. Therefore, it’s crucial to monitor the water table levels and adjust your pump’s operation accordingly.

How to Calculate the Amperage of a 1.5 HP Well Pump

As a homeowner with a well pump system, you know how important it is to maintain a steady supply of clean water. However, without understanding the electrical requirements of your well pump, you may be putting your system at risk.

Calculating the amperage of your 1.5 HP well pump is an essential step in ensuring the safe and efficient operation of your system. Here’s what you need to know:

Determining the Voltage of Your Well Pump System

Before you can calculate the amperage of your well pump, you need to know the voltage of your system. Most well pumps operate on either 120 volts or 240 volts. You can typically find this information on the motor plate or in the manufacturer’s documentation.

Using the Formula to Calculate Amperage

Once you know the voltage of your system, you can use a simple formula to calculate the amperage:

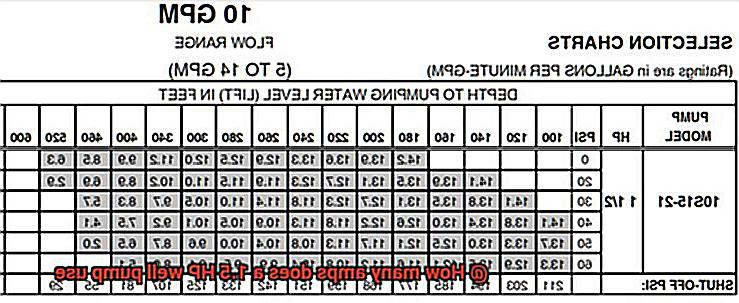

Amperage = Horsepower x 746 ÷ Voltage

For a 1.5 HP well pump operating at 120 volts, the amperage would be around 9.3 amps. If your well pump operates at 240 volts, the amperage would be around 4.65 amps.

Proper Sizing and Installation

Calculating the amperage of your well pump is crucial for determining the correct size wire and breaker needed for installation. For most well pumps, wire sizes range from #10 to #12, and circuit breaker sizes range from 15 amps to 20 amps.

It’s important to remember that these calculations are based on the operating horsepower of the pump, not the peak horsepower. Peak horsepower can be higher during start-up or other high-demand situations, so it is recommended to consult with a professional electrician or well pump installer to ensure proper sizing and installation.

Consulting with Experts

If you are unsure about how to properly calculate the amperage of your well pump or if you need any assistance with installation or maintenance, it’s always a good idea to consult with a licensed electrician or well pump technician. They can help you navigate the electrical requirements of your system and ensure that everything is installed and maintained properly.

The Average Amperage Draw of a 1.5 HP Well Pump

In this article, we’ll explore everything you need to know about the average amperage draw of a 1.5 HP well pump and what factors can impact it.

First things first, let’s talk about voltage. Most well pumps operate on either 120 volts or 240 volts, and the amperage draw will vary based on the voltage. Assuming a 240-volt system, a 1.5 HP well pump typically draws around 10 amps during normal operation. However, during startup, the amperage draw can spike up to 50 amps or more, depending on the specific pump and motor.

But there are other factors to consider as well. One of them is the depth of the well. The deeper the well, the harder your pump has to work to lift water to the surface, which can increase its amperage draw. Another factor is the length of the pipe. Longer pipes create more resistance and make it harder for the pump to move water through them, which can also increase its amperage draw. Lastly, any restrictions in the system such as clogged filters or closed valves can cause your pump to work harder and draw more amps.

So how do you measure your well pump’s amperage draw? You’ll need an ammeter or multimeter, which you can purchase at your local hardware store. Simply place the meter in-line with one of the power leads and measure the amperage draw during normal operation and startup.

It’s important to ensure that your well pump is not drawing too many amps, as this can indicate a problem with the system. If you notice a significant increase in amperage draw or any other issues with your well pump, it’s best to call in a professional for an inspection and potential repairs.

Variations in Amperage Draw Depending on Load

In our last section, we discussed how the amperage draw of a 1.5 HP well pump can vary depending on load. Today, we’re going to dive deeper into what exactly load means and how it affects your pump’s energy consumption.

Firstly, let’s talk about the depth of your well. The deeper the well, the harder your pump has to work to bring water to the surface. This increased workload results in a higher amperage draw. So, if you have an especially deep well, brace yourself for your pump to use more energy and draw more amps.

Next up is the diameter of your well casing. If your casing has a smaller diameter, it will restrict water flow and force your pump to work harder. This added workload also leads to higher amperage draw.

Lastly, pressure tanks can also impact amperage draw. If your tank is too small, it will cause your pump to cycle more frequently. This increase in cycling will lead to a higher amperage draw as well.

It’s essential to note that a higher amperage draw equals more energy consumption and, ultimately, higher electricity bills. To avoid this, it’s crucial to have your well pump regularly maintained and serviced by a professional.

One way to regulate energy consumption and reduce amperage draw is by choosing a variable speed drive pump. This technology adjusts the speed of the pump motor based on demand and can significantly reduce energy usage.

Ensuring Your Electrical System Can Support Your Well Pump

Worry not, as there are a few key factors that can help ensure your well pump runs seamlessly and efficiently.

Firstly, it’s essential to ensure that your electrical service is equipped to handle the job. A 1.5 HP well pump requires a dedicated circuit with a 20-amp breaker. Therefore, your wiring and breaker must be able to support at least 20 amps of current without tripping or overheating.

It’s also important to consider the distance between your well pump and electrical panel. Longer distances can cause voltage drop and reduced performance. To address this issue, use larger gauge wire for longer runs, and install a voltage booster or capacitor at the well pump to compensate for any drop in voltage.

Another critical factor is the overall load on your electrical system. Running multiple high-powered appliances at once can put undue stress on your system and potentially damage your well pump. To avoid this, stagger the use of appliances and avoid running multiple devices simultaneously whenever possible.

Lastly, it’s crucial to ensure that all wiring and connections are installed correctly and grounded appropriately. Any loose or damaged wires can pose safety hazards and affect performance. So, it’s always best to have a licensed electrician inspect your system periodically to ensure everything is in top working order.

WgIA19fmvV8″ >

Conclusion

To wrap things up, a 1.5 HP well pump is an indispensable tool for pumping water from a well into your home or business. Understanding the number of amps it uses is vital for connecting it to a generator or inverter with specific power ratings. Several factors influence the amperage draw of a 1.5 HP well pump, including voltage and motor size, well depth, pipe length, and system restrictions.

To ensure safe and efficient operation, calculating the amperage of your 1.5 HP well pump is critical. You can use a straightforward formula based on horsepower and voltage to determine the amperage. During installation, selecting appropriately sized wires and circuit breakers is also essential.

Variable speed drive pumps are an excellent solution for regulating energy consumption and reducing amperage draw by adjusting the speed of the pump motor based on demand.

For seamless and efficient operation, it’s crucial to ensure that your electrical system can support your well pump. Factors such as distance between your well pump and electrical panel, overall load on your electrical system, and proper installation and grounding of wiring connections must be considered.

Consulting licensed electricians or well pump technicians can help you navigate the electrical requirements of your system and guarantee that everything is installed correctly and maintained properly.