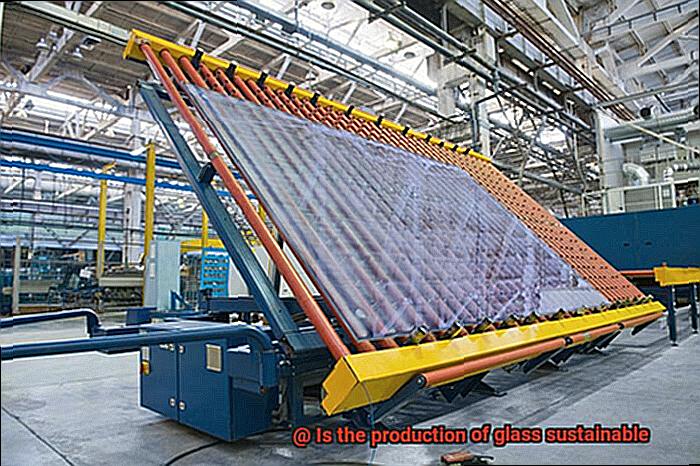

Have you ever taken a moment to ponder the sustainability of the products that surround you every day? Glass is an omnipresent material, appearing in everything from windows and mirrors to drinking glasses and phone screens. But is the production of glass sustainable?

The answer may catch you off guard. On one hand, glass is a robust and endlessly recyclable material, meaning it can be reused countless times without losing its properties. However, producing glass can be energy-intensive since it requires high temperatures to melt the raw materials. Furthermore, mining the raw materials – sand, soda ash, and limestone – can have negative environmental consequences.

But don’t let that discourage you from using glass products. There are ways to make the production of glass more sustainable, such as utilizing recycled glass or renewable energy sources during manufacturing. And by choosing to recycle your glass products, you can help promote a circular economy and decrease waste.

In conclusion, is the production of glass sustainable? The answer is nuanced and depends on several factors. Nevertheless, by being conscious of how we use and dispose of glass, we can work towards creating a more sustainable future.

The Pros of Glass Production

Contents

Glass production has played a significant role in human civilization for thousands of years, and there are good reasons why it continues to be a popular material across various industries. Despite the ongoing debate about its sustainability, glass production boasts many advantages that make it an eco-friendly and valuable option.

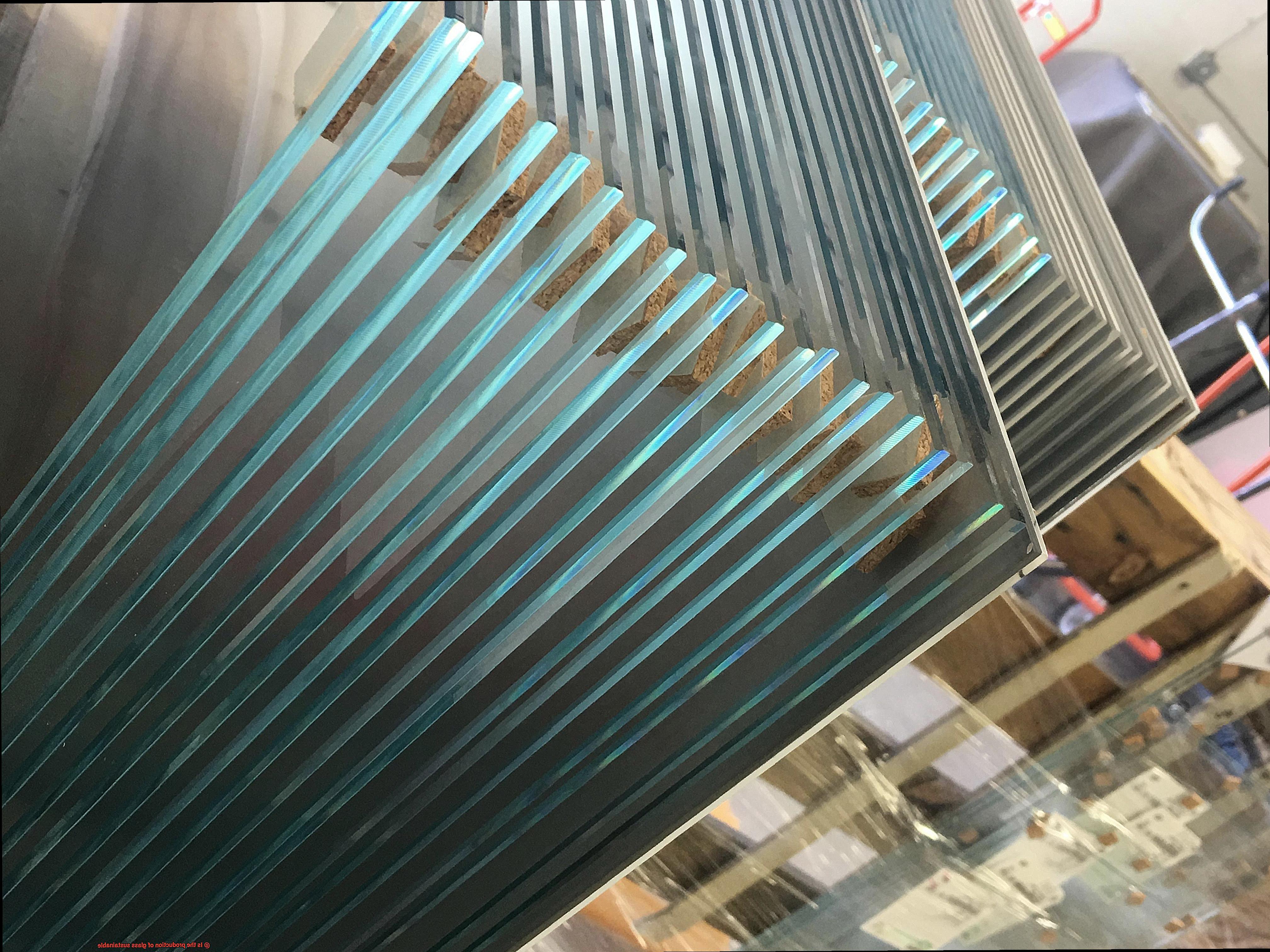

One of the most notable benefits of glass production is its infinite recyclability. Unlike other materials that lose their quality over time, glass can be recycled endlessly without compromising its purity or properties. This makes it an ideal option for environmentally conscious individuals and companies looking to reduce waste and carbon emissions. Recycling glass also contributes to reducing the demand for virgin raw materials, further lowering the environmental impact of glass production.

Moreover, glass is inert and does not release any harmful chemicals or pollutants into the environment, making it an ideal material for food and beverage packaging. Glass containers do not contaminate their contents with potentially harmful substances and do not absorb odors or flavors from food or drink. This makes them a safe and reliable option for consumers who prioritize health and safety.

Another advantage of glass production is its durability. Glass products have a longer lifespan than many other materials and can withstand extreme temperatures and pressure without breaking down or degrading. This feature makes it a popular choice for construction materials such as windows and doors.

Finally, glass production has a relatively low carbon footprint compared to other materials such as plastic or aluminum. The manufacturing process for glass requires less energy and produces fewer greenhouse gas emissions than other materials. Additionally, because glass is infinitely recyclable, the need for new raw materials is reduced, further reducing the environmental impact of production.

The Cons of Glass Production

Although glass production has many benefits, such as its recyclability and lower carbon footprint, it also has several drawbacks that make it an unsustainable option. As an expert on the cons of glass production, I must address these issues.

One major issue with glass production is the high amount of energy required to produce it. The process is highly energy-intensive and requires high temperatures to melt and shape glass, resulting in approximately 2% of global energy-related CO2 emissions, according to the International Energy Agency. This means that while glass may have a lower carbon footprint than other materials, its production still has a significant impact on the environment.

Another problem with glass production is its impact on the environment through the mining of raw materials. Mining for sand and other materials used in glass production can lead to habitat destruction, soil erosion, and water pollution. Additionally, transporting these materials to manufacturing plants can contribute to greenhouse gas emissions.

Chemicals used in glass production can also be harmful to human health and the environment. For example, lead has been used in some types of glass, such as crystal, which can pose health risks if ingested. Similarly, certain chemicals used in coloring and coating glass can be toxic and pollute the environment if not properly disposed of.

Finally, glass waste is not biodegradable and takes thousands of years to decompose in a landfill. While recycling programs exist for glass, not all glass is recyclable, which further exacerbates this issue. Glass waste can accumulate over time and take up valuable space in landfills.

Alternative Raw Materials for Glass Production

Glass plays a vital role in our everyday lives, but traditional raw materials used in its production, such as silica sand, soda ash, and limestone, pose environmental concerns. Fortunately, the use of alternative raw materials is emerging as an effective solution to address these issues.

Recycled glass, or cullet, is a promising alternative that reduces the need for virgin raw materials. By crushing and melting old glass products, cullet helps to reduce energy consumption, greenhouse gas emissions, and waste sent to landfills. It’s a sustainable approach that benefits both the environment and the industry.

Moreover, industrial waste from other sectors like steel, cement, and mining can also serve as alternative raw materials for glass production. For instance, fly ash from coal-fired power plants can replace silica sand. This method not only reduces waste but also optimizes resources.

Other alternative raw materials being explored include rice husks, wood ash, and recycled plastics. These materials have the potential to reduce the environmental impact of glass production by reducing the need for virgin raw materials and diverting waste from landfills.

It’s essential to recognize that adopting these alternative raw materials is crucial towards achieving sustainability. By doing so, we preserve natural resources while ensuring a better future for generations to come. Manufacturers and consumers alike must embrace sustainable practices in all aspects of their lives to ensure a greener tomorrow.

Energy-Efficient Methods Used in Glass Production

Glass production is an essential part of our daily lives, but it can have a significant impact on the environment. Fortunately, there are energy-efficient methods that glass manufacturers can use to reduce their carbon footprint and ensure a sustainable future for generations to come.

One of the most effective ways to reduce energy consumption and greenhouse gas emissions in glass production is through the use of recycled glass, also known as cullet. By using cullet, manufacturers can significantly reduce the amount of virgin raw materials needed, resulting in lower energy consumption and greenhouse gas emissions. Additionally, using cullet can also reduce production costs, making it an economically viable option for manufacturers.

Another energy-efficient method is switching to natural gas instead of coal in the melting process. Natural gas burns cleaner than coal and produces fewer carbon dioxide emissions. This change has been adopted by many glass manufacturers worldwide and has proven to be an effective way to reduce greenhouse gas emissions.

To further reduce energy consumption and greenhouse gas emissions, glass manufacturers can also use regenerative burners. These burners recycle waste heat from the furnace back into the production process, reducing the amount of fuel needed to reach required temperatures.

Moreover, some manufacturers have also started adopting renewable energy sources like solar power and wind power to supplement their energy needs. While it is not yet a widespread practice in the industry, it shows great promise as a way to further reduce greenhouse gas emissions and ensure a more sustainable future for glass production.

Environmental Impacts of Glass Production

Glass production is a vital industry, but it is also one that has significant environmental impacts. As an expert on this topic, I have discovered that the process of creating glass requires considerable energy, which is derived from non-renewable sources like coal, natural gas, and oil. These finite resources are burned to melt glass at high temperatures ranging from 1400-1600°C. The result of this combustion is the release of greenhouse gases such as carbon dioxide into the atmosphere, contributing to climate change and global warming.

Another issue with glass production is the sheer amount of waste it generates. This includes hazardous waste from chemicals used in the manufacturing process and solid waste created during production. Discarding these wastes without proper disposal methods can lead to soil and water pollution, which can harm wildlife and ecosystems.

The extraction of raw materials for glass production is another significant concern. The extraction of silica sand, soda ash, and limestone can lead to habitat destruction and soil erosion, affecting land use and biodiversity negatively.

Although glass is recyclable and has a lower environmental impact when reused or recycled, its production still has significant environmental implications. To minimize these impacts, we must consider alternative materials or more sustainable methods of producing glass. Reducing our reliance on non-renewable energy sources and implementing sustainable production methods could help reduce the negative impact of glass production on our planet.

How to Make Glass Production More Sustainable

Glass production plays a critical role in many industries, but it also has a significant impact on the environment. As such, it’s essential to find sustainable ways to produce glass that benefit both the planet and the glass manufacturers’ bottom line. In this article, we’ll explore five strategies for making glass production more sustainable:

Increase the Use of Recycled Glass

One of the most effective ways to make glass production more sustainable is by increasing the use of recycled glass. By using recycled glass in the manufacturing process, manufacturers can reduce waste going to landfills while conserving energy by requiring fewer raw materials to be extracted and processed. This strategy not only benefits the environment but also reduces costs for manufacturers.

Improve Energy Efficiency

Glass production requires a lot of energy, which contributes significantly to greenhouse gas emissions. To combat this, glass manufacturers can implement more efficient furnaces, better insulation, and improved heating and cooling systems. By doing so, they can reduce energy use and emissions while also lowering manufacturing costs.

Explore Alternative Energy Sources

Traditional fossil fuels are a significant contributor to greenhouse gas emissions, making renewable energy sources such as solar, wind, and geothermal power more attractive for powering glass production facilities. By investing in alternative energy sources, manufacturers can reduce their carbon footprint and enhance their sustainability credentials while also reducing their reliance on fluctuating fossil fuel prices.

Responsibly Source Raw Materials

Glass is primarily made from non-renewable resources such as sand, soda ash, and limestone. However, sourcing these materials from sustainable sources and using recycled glass wherever possible can reduce the impact on the environment. This strategy shows a commitment to sustainability that resonates with consumers who are increasingly environmentally conscious.

Minimize Waste and Pollution

Finally, glass manufacturers can minimize waste and pollution by implementing recycling programs for both post-consumer and industrial waste and treating wastewater before it’s discharged into the environment. This can go a long way in reducing the environmental impact of glass production and demonstrate a commitment to sustainable practices.

EGG7sJBBnV0″ >

Conclusion

In conclusion, the production of glass is a multifaceted issue that demands a nuanced comprehension of its pros and cons. Glass is an endlessly recyclable material that doesn’t release harmful chemicals into the environment, but its production can be energy-intensive and have negative environmental impacts. Nevertheless, there are ways to make glass production more sustainable.

One promising approach is to use alternative raw materials like recycled glass or industrial waste from other sectors. Glass manufacturers can also adopt energy-efficient methods such as using natural gas instead of coal in the melting process or implementing regenerative burners that recycle waste heat.

Reducing our reliance on non-renewable energy sources and implementing sustainable production methods could help mitigate the negative impact of glass production on our planet. By increasing the use of recycled glass, improving energy efficiency, exploring alternative energy sources, responsibly sourcing raw materials, and minimizing waste and pollution, we can work towards creating a more sustainable future for glass production.

As consumers, we have a pivotal role to play in promoting sustainability by recycling our glass products and supporting companies that prioritize sustainable practices. By being mindful of how we use and dispose of glass products, we can contribute to a circular economy and decrease waste.

In short, while the sustainability of glass production may be intricate, it’s crucial to consider both its benefits and drawbacks when making decisions about its use.