Are you a woodworking enthusiast who loves nothing more than spending hours in your workshop, creating beautiful pieces with your trusty table saw? Or perhaps you’re a professional carpenter who relies on your table saw day in and day out to get the job done. Either way, it’s crucial to understand the power requirements of your tool for optimal performance and safety.

If you’re curious about the amps required for a table saw, look no further. As an expert in all things tools, I’m here to help clear up any confusion about power consumption. You might be surprised to learn that the amps a table saw uses can vary based on factors like blade size, motor capacity, and voltage.

In this informative post, we’ll explore the primary factors that determine how many amps a table saw uses. We’ll also provide tips on what to look for when purchasing a new table saw and how to use it safely and efficiently. Whether you’re a seasoned woodworker or just starting out, understanding your tool’s power requirements is essential for achieving great results while keeping yourself and your equipment safe.

So let’s dive right in and learn everything there is to know about how many amps your table saw requires.

What is an Amp?

Contents

An amp, also known as an ampere, is a unit of electrical current that measures the flow of electric charge through a circuit over time. Think of it like the rate of water flowing through a pipe.

When it comes to using your table saw, understanding amps is vital. The amount of power your saw requires is measured in amps, which refers to the amount of electrical current being drawn by the saw. Generally, most table saws require a minimum of 15 amps to operate, with some requiring up to 20 amps or more. The amperage may vary depending on factors such as the size and power of the motor or the type of blade being used.

It is crucial to note that while your table saw may be rated for a specific amperage, it may not always draw that amount of power. For instance, most saws will only draw their maximum amperage when under heavy load, such as when cutting thicker or harder materials.

Overloading a circuit with too many amps can result in blown fuses, damaged equipment or even electrical fires. Therefore, it’s essential to ensure safe and efficient usage of your table saw by knowing the amp rating of your device and ensuring it is being used on circuits that can handle its power needs.

In conclusion, comprehending what an amp is and how it relates to your table saw is crucial for safe and efficient operation. Picture it like water flowing through a pipe – amps measure the rate of electrical flow while volts measure the force or pressure behind that flow. By grasping these fundamental principles, you can guarantee that your equipment operates smoothly and without incident.

How to Determine the Amperage of a Table Saw

Determining the amperage of your tool is essential in avoiding potential hazards and ensuring efficient operation. In this blog post, we’ll take a closer look at how to determine the amperage of a table saw with five subtopics to make it easier for you.

Find the Amperage Rating

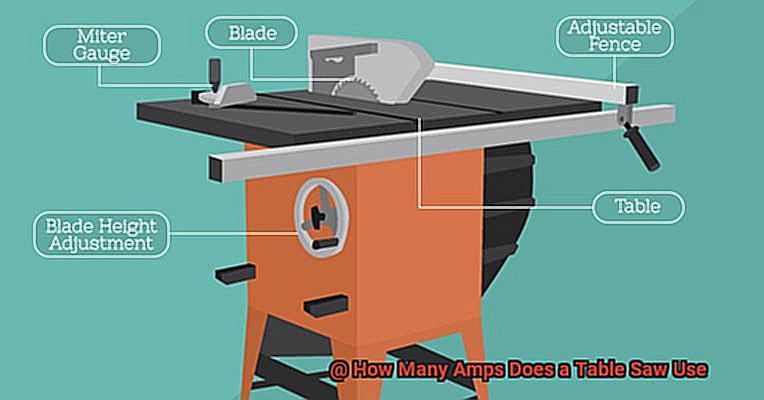

The motor’s rating plate on your table saw is your go-to source for all the necessary information, including the amperage rating. It’s typically located on the side or back of the saw and provides information about the motor’s voltage, horsepower, and amperage. Remember that the amperage listed on the rating plate is the maximum amperage that the motor can draw under load.

Measure Actual Amperage Draw

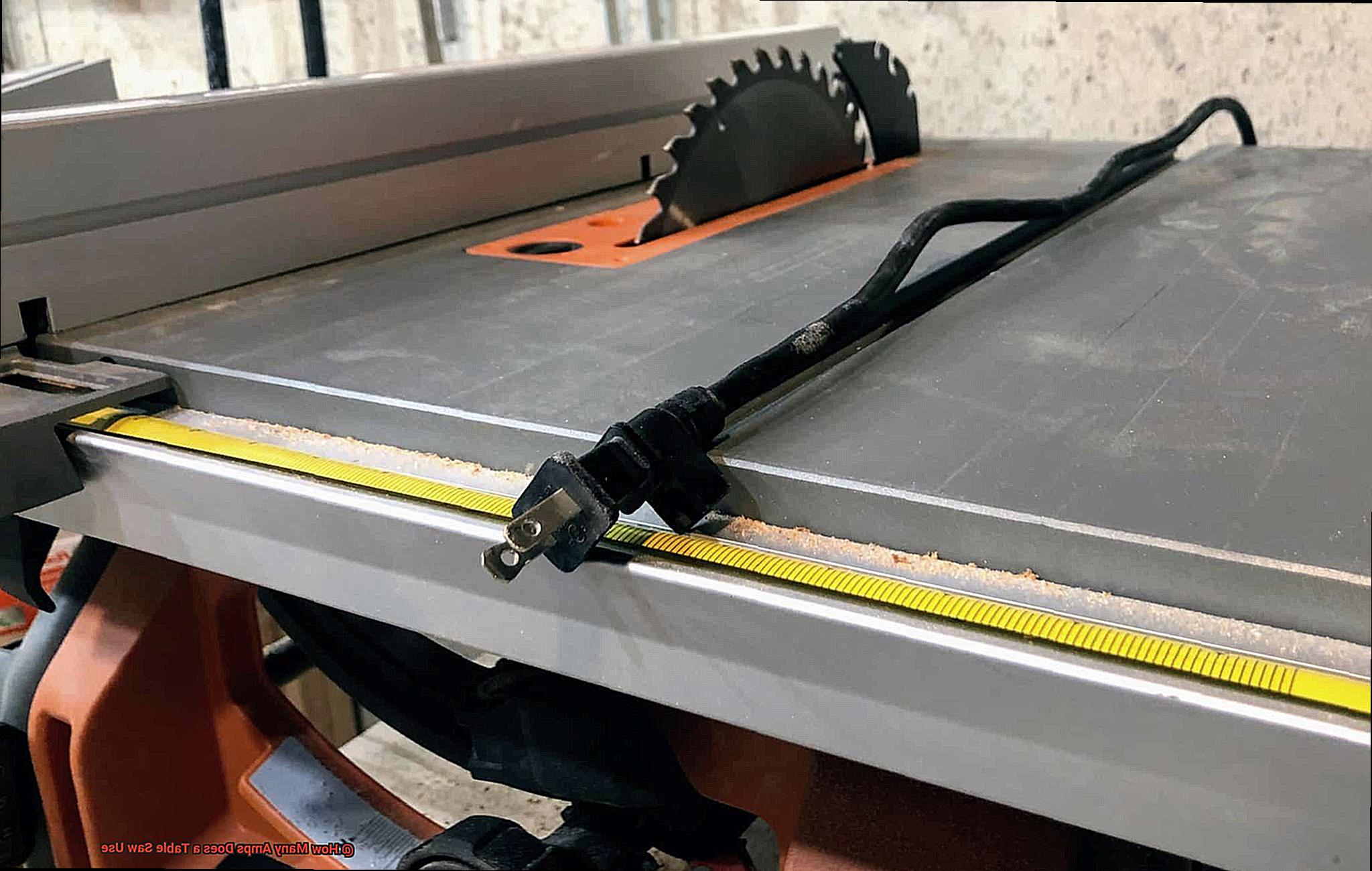

For a more accurate measurement of the amperage drawn by your table saw, you can use a clamp-on ammeter. This device clamps around one of the power cords leading to the saw and measures the current flowing through it. Safety must be a priority when using an ammeter, so read and understand the manufacturer’s instructions before use.

Understand Continuous Running Amperage

The amperage rating listed on your table saw is not its continuous running amperage but rather its maximum draw under load. Knowing this will help you choose the right circuit breaker and extension cord for your tool.

Use Properly Rated Extension Cords

Using an extension cord with a lower capacity than what your tool requires can cause overheating and damage to both the extension cord and your tool. To avoid this, ensure that you use an extension cord rated for at least the same amperage as your table saw and never use an extension cord longer than necessary.

Choose The Right Circuit Breaker

Choosing the right circuit breaker is crucial in ensuring safe and efficient operation. It’s recommended to use a dedicated 20-amp circuit for table saws rated at 2 horsepower or less and a dedicated 30-amp circuit for table saws rated higher than 2 horsepower. This will prevent overloading and potential hazards.

In conclusion, determining the amperage of your table saw is essential in ensuring safe and efficient operation. By following these guidelines and using proper equipment, you can make sure that your table saw is running at its best while prioritizing your safety.

Factors That Affect Amperage

Today, we’re going to uncover the secrets behind amperage consumption by a table saw. Amperage is a unit of measurement for electrical current, and it’s crucial for determining the safe and efficient operation of your saw.

There are several factors that affect amperage consumption, starting with the type and size of your saw. A larger saw with a more powerful motor will generally use more amps than a smaller one with less power. It’s simple math – more power requires more electricity to flow through the circuit.

But there’s more to it than just the size of your saw. The voltage of your power supply can also impact amperage usage. If your voltage is lower than what’s recommended for your saw, it may draw more amps to compensate for the lower energy input. So be sure to use a power supply that matches your saw’s specifications.

The materials you’re cutting also play a role in amperage usage. Thicker or denser materials require more power to cut through, resulting in higher amperage consumption. If you frequently work with dense hardwoods or other tough materials, you’ll want a saw with enough power to handle the job without overloading on amps.

The condition of your blade is another factor to consider. A dull or damaged blade may require more energy to cut through materials, leading to increased amp usage. Keep your blades sharp and in good condition to ensure smooth and efficient operation.

Finally, let’s talk about extension cords. Did you know that using an extension cord that is too long or too thin can impact amperage usage? A longer or thinner cord can restrict the flow of electricity and cause your saw to draw more amps than necessary. To avoid this, use a heavy-duty extension cord that is no longer than necessary for the job at hand.

By understanding these factors that affect amperage consumption by a table saw, you can make informed decisions when selecting a saw for your woodworking projects.

Safety Considerations When Using a Table Saw

However, it’s crucial to remember that safety should always come first when using this equipment. Here are some important safety considerations to keep in mind:

To start, dressing appropriately is key. Loose clothing and jewelry can easily get caught in the saw, causing serious injuries. So, wearing fitted clothing and avoiding anything that could be a potential hazard is essential.

Another key factor in staying safe while using a table saw is protecting your eyes and ears. The saw produces a lot of noise and sawdust that can harm your vision and hearing. Always wear protective goggles and earplugs to prevent any debris from getting into your eyes or causing hearing damage.

Keeping your workspace clear is also important for safety. Make sure you have enough space around the saw to move around comfortably, and keep the area free of clutter or debris that could interfere with your work.

When cutting small pieces of wood, using a push stick can help keep your fingers away from the blade. This simple tool is an effective way to prevent accidental injuries and keep your hands safe.

Finally, always turn off the power before adjusting or changing the blade, and never leave the saw running unattended. Accidents can happen even with the most careful use of a table saw, so taking precautions to protect yourself and those around you is crucial.

Using a table saw can be an enjoyable and rewarding experience if you prioritize safety. By following these simple safety considerations, you can ensure that you are using your table saw safely and responsibly.

Types of Table Saws and Their Amperage Requirements

With so many types available, it can be overwhelming to know which one to choose. In this article, we’ll guide you through the different types of table saws and their respective amperage requirements, so you can make an informed decision.

Let’s start with the smallest type: benchtop saws. These portable saws are perfect for hobbyists or those with limited space. They typically require around 10 amps of electricity to function properly, making them the compact car of table saws – small but efficient.

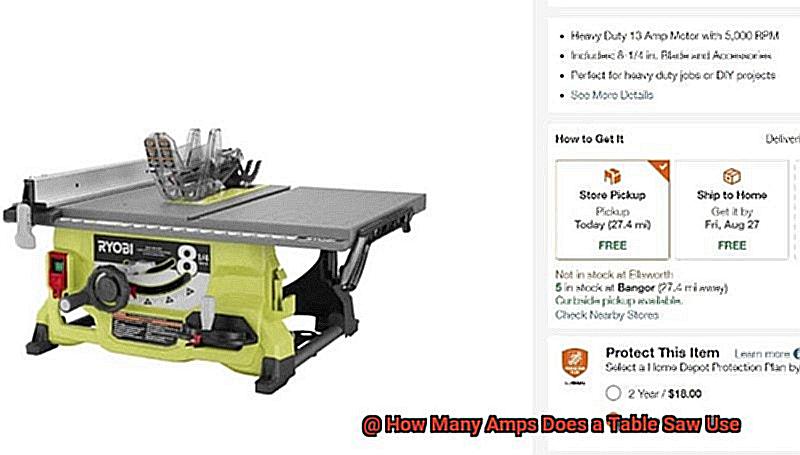

Next up are contractor saws, larger and more powerful than benchtop saws. These saws are a popular choice for professional contractors and usually require between 13-15 amps of electricity. Think of them as the SUVs of table saws – powerful and efficient.

For those looking for the most powerful and expensive type of table saw, look no further than cabinet saws. Typically used in industrial settings, these saws require a significant amount of power to operate, with most requiring at least 20 amps of electricity. Think of them as the sports cars of table saws – high-powered and built for speed.

But what if you want the power of a cabinet saw without the price tag? Enter hybrid saws, a combination of contractor and cabinet saws. They offer the best of both worlds, with a lower price tag and requiring around 14-15 amps of electricity to function properly. Think of them as the crossover SUVs of table saws.

It’s important to remember that amperage requirements can vary depending on the specific model and brand of table saw.

Always consult the manufacturer’s specifications before making a purchase and ensure that your electrical circuit can handle the required amperage. Failure to do so can result in damage to your equipment or even a fire hazard.

Conclusion

As a tool expert, I know that understanding the amperage required for your table saw is crucial for both optimal performance and safety. By taking into account factors like blade size, motor capacity, and voltage, you can determine how many amps your saw needs to operate efficiently. Generally speaking, most table saws require at least 15 amps to run properly, while some may need up to 20 amps or more.

To ensure safe and efficient usage of your table saw, it’s important to determine its amperage rating. You can find this information on the motor’s rating plate or use a clamp-on ammeter for more accurate measurement. Other considerations include understanding continuous running amperage, using properly rated extension cords, and choosing the right circuit breaker.

Several factors impact how much amperage a table saw uses, such as the type and size of the saw, voltage of power supply, materials being cut, condition of blade, and extension cords used. To stay safe when using a table saw, make sure to dress appropriately, protect your eyes and ears with goggles and earplugs, keep your workspace clear of clutter, use push sticks when cutting small pieces of wood, turn off power before adjusting or changing blades, and never leave the saw running unattended.

It’s worth noting that different types of table saws have varying amperage requirements. For example, benchtop saws typically require around 10 amps while cabinet saws need at least 20 amps. Before making a purchase decision based on amperage requirements alone though it is important to consult manufacturer specifications to ensure electrical circuits can handle required amperage.